Hello, this is Drew Slocum with Inspect Point. Here to go over a few key visual inspection tips for a kitchen suppression system. The monthly visual inspection is usually done by the owner or the kitchen manager. Occasionally, it might be done by an authorized distributor. However, the authorized distributor or kitchen suppression specialist is called in on a semi-annual basis or on any activation of the system. So, on the monthly visual, we're looking for proper placement of the hazard to ensure full nozzle coverage. All the nozzles should be in place and pointed directly at the hazard with blow-off caps on. Additionally, we want to check the duct for excessive buildup of grease, dirt, or any other debris. It's also important to inspect the plenum and airway to ensure the presence of a nozzle with a blow-off cap. Moving on to the suppression system, we have the open gas valve, shutoff valve, or electric valve located here. When examining the suppression system, we need to ensure that it is green and in the fully cocked position. Next, we have the manual actuator, which should be free from any damage. There is also a tamper device present to alert us in case someone attempts to tamper with or pull the system. After completing the monthly visual inspection, don't forget to check the tag to ensure that the authorized distributor or service technician has tagged it on a semi-annual basis. Once everything is in order, we can resume cooking. Thank you.

Award-winning PDF software

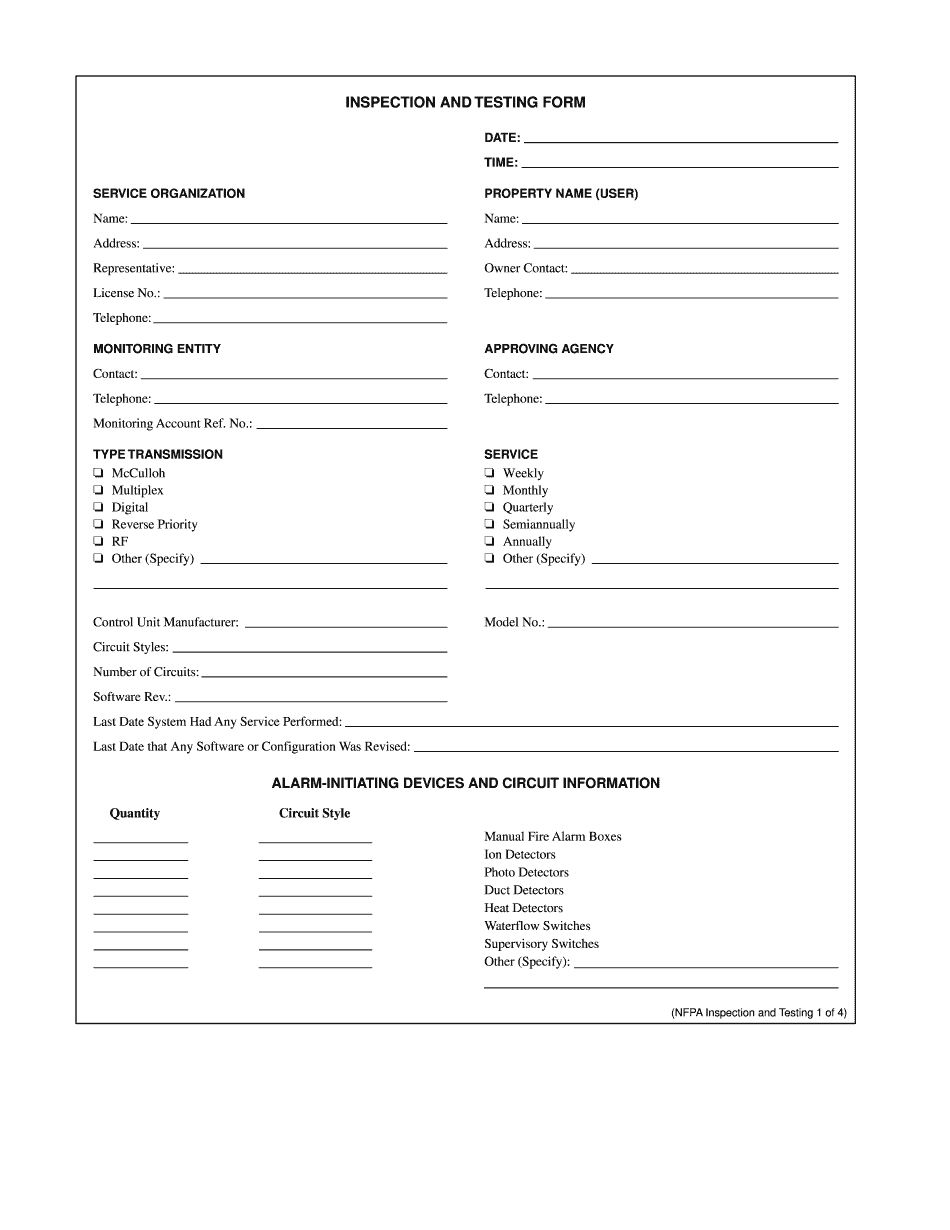

Nfpa inspection s Form: What You Should Know

State Fire Marshal Documentation Forms: Sprinkler Systems — Inspection or Test (AES 3). NFPA 25 Form AES 3.1 Quarterly Annual Wet Pipe 2013.pdf. State Fire Marshal Documentation Forms: Sprinkler Systems — Maintenance (AES 3). NFPA 25 Form AES 3.1 Quarterly Annual Wet Pipe 2013.

online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do NFPa inspection and Testing, steer clear of blunders along with furnish it in a timely manner:

How to complete any NFPa inspection and Testing online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our assistance team.

- Place an electronic digital unique in your NFPa inspection and Testing by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your NFPa inspection and Testing from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Nfpa Inspection Forms